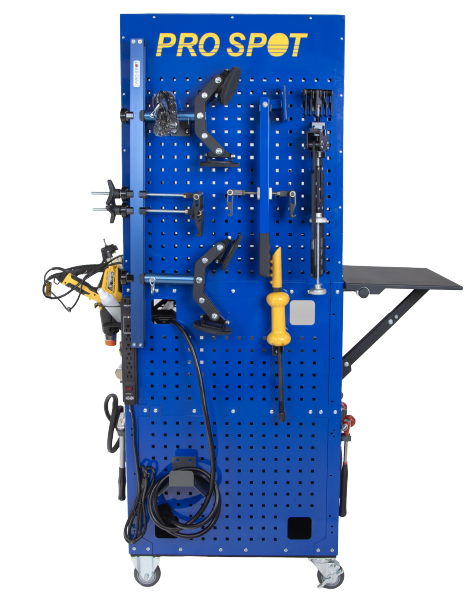

MWS-GTK-AL | Aluminum and Glue Dent Repair Station

- Brochure - 471.1 KB

- Component List - 553.9 KB

- Glue Tab Kit Component List - 344.9 KB

- Dent Repair Stations Comparison - 574.8 KB

- PRO-GTK Knowledge Center

Introducing the MWS-GTK-AL station, the professional solution for your dent repair needs. With the DA-3 Drawn Arc Welder, the PRO-GTK Glue tab kit and a variety of pulling tools on one mobile station, you can repair any dent anywhere in the shop.

The MWS-GTK-AL station also offers a wide range of dent pulling accessories and tools. These added tools give technicians the ability to pull any dent on any material.

The station provides plenty of storage space with lockable drawers and tool hooks and customization opportunities.

-

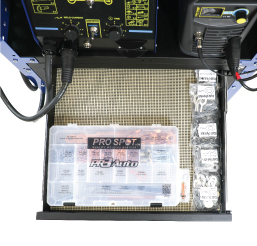

Drawers for convenient tools storage

The MWS-GTK-AL is ergonomically designed to help you support tools, accessories, and equipment. One easily accessible location for all of your dent pulling accessories.

-

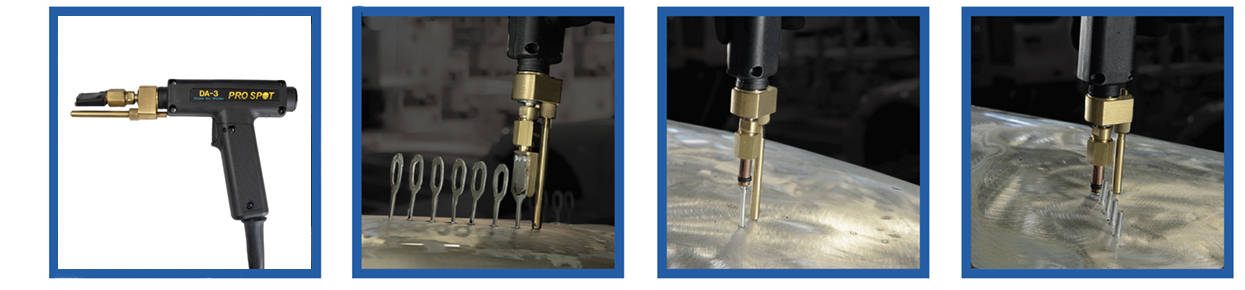

DA-3 for effective Aluminum Repair

Synergic Drawn Arc welder that works with Aluminum and Steel.

-

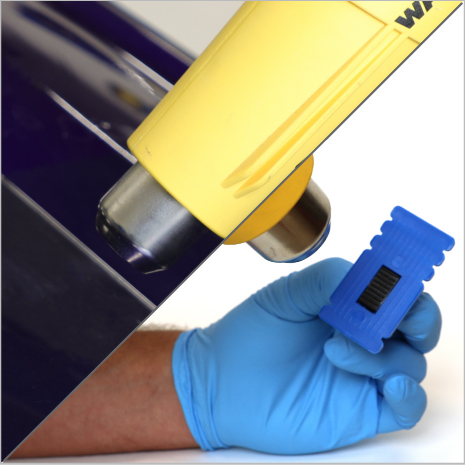

PRO-GTK Glue Tab Dent Repair Kit

This kit works on Aluminum and Steel, directly on painted materials. No need to grind.

DA-3 for effective Aluminum Repair

The Pro Spot DA-3 Synergic Drawn Arc welder easily applies pulling keys and threaded studs so that various tools can be used to pull dents from steel and aluminum panels. With specific programs for both steel and aluminum, the DA-3 features:

- • Different functions for a variety of repair procedures

- • Color graphics screen for easy and intuitive set up

- • Customizable and storable weld programs

- • SD card memory to update and add programs

- • Extremely lightweight

The DA-3 has a wide range of configurations to best fit your shop’s needs. It can be added to a weld cart or even a Mobile Weld or Dent Pulling station for additional functionality, mobility and storage.

LEARN MORE | DA-3 BROCHURE | DA-3 COMPONENT LIST

Aluminum Repair Using Drawn Arc Technology

GLUE TAB DENT REPAIR KIT

Fix major dents with no heat input. This is crucial when repairing new advanced, heat sensitive materials such as HS steel and aluminum. They demand new processes to repair these materials with little or no heat input and the Pro Spot Glue Tab Dent Repair Kit is the answer. It will help with your dent repair process by avoiding welding or arc procedures, significantly cutting repair time.

Features:

• Repair Without Damaging The Undercoat: Designed for the growing needs to repair new, advanced metals without damaging the undercoat.

• Quickly Pull Dents: The Glue Kit allows users to quickly pull dents without having to grind the repair area.

Just the Right Types and Amount of Glue Tabs

We include only the tabs that most technicians need for repairs…no added tabs or cluttered workspace with unnecessary tabs.

Glue tabs, hooks, pullers and other required equipment are neatly organized in two sliding drawers. Each compartment is labeled with the type of products and a QR Code for training and easy reordering.

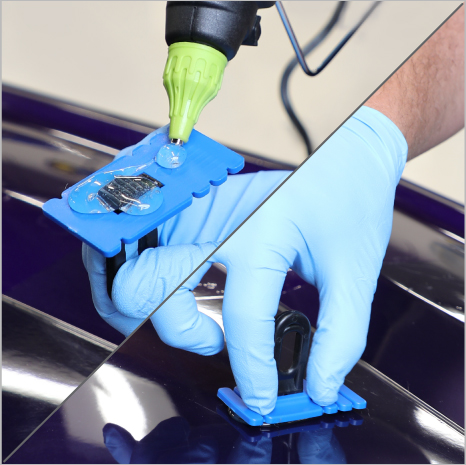

Glue Tabs are Applied In Four Easy Steps!

-

Step 1: Plug in the glue gun. This way it will be hot and ready when the area and tabs are prepared.

-

Step 2: Clean the are you are planning to repair with 91% alcohol.

-

Step 3: Heat the area you are repairing to remove excess moisture, no more than 100 degrees and the tab you are using to pull.

-

Step 4: Put glue on the tab you are going to pull and then apply it to the area you are repairing.

MWS-GTK-AL Equipment and Accessories

- Mobile Work Station G2

- 110V Power Strip, 6-Outlet, 2-USB

- DA-3 220V: Drawn Arc Dent Puller

- PRO-GTK: Glue Tab Kit (110V)

- 85-0200: Heat Gun (110V)

- 85-3088: Air Grinder

- 85-0421: Infrared Laser Thermometer

- SA-0032: AL Hammers, 3 Piece Set

- 85-1277 7pc Steel Hammer & Dollie Set

- PRO-66: Pro Pull, Dent Puller

- PB-20: Pivot Puller

- PB-10: Pull Bar 4-footed

- PRO-65: Pull Gun Assembly

- PRO-GT3D: 3D Glue Tabs

- PRO-GTFT: Universal Flat Glue Tabs (18PC kit)

- Multiple mounting Accessories

WORK STATION TECHNICAL SPECIFICATIONS

| Work Station Dimensions: |

|

| Part Number: | MWS-GTK-AL |

| Weight: (With all equipment) |

|